Thread Rolling: Advantages and Applications in Steel | Pamexpol

The thread rolling process is an advanced metal forming technology widely used in the steel industry to produce high-quality threaded components. Unlike traditional thread cutting, this method does not remove material but instead shapes it through deformation, ensuring exceptional strength and precision. In today’s Pamexpol blog post, we explain how thread rolling works, its advantages, and where it is used in steel structures.

What is the thread rolling process?

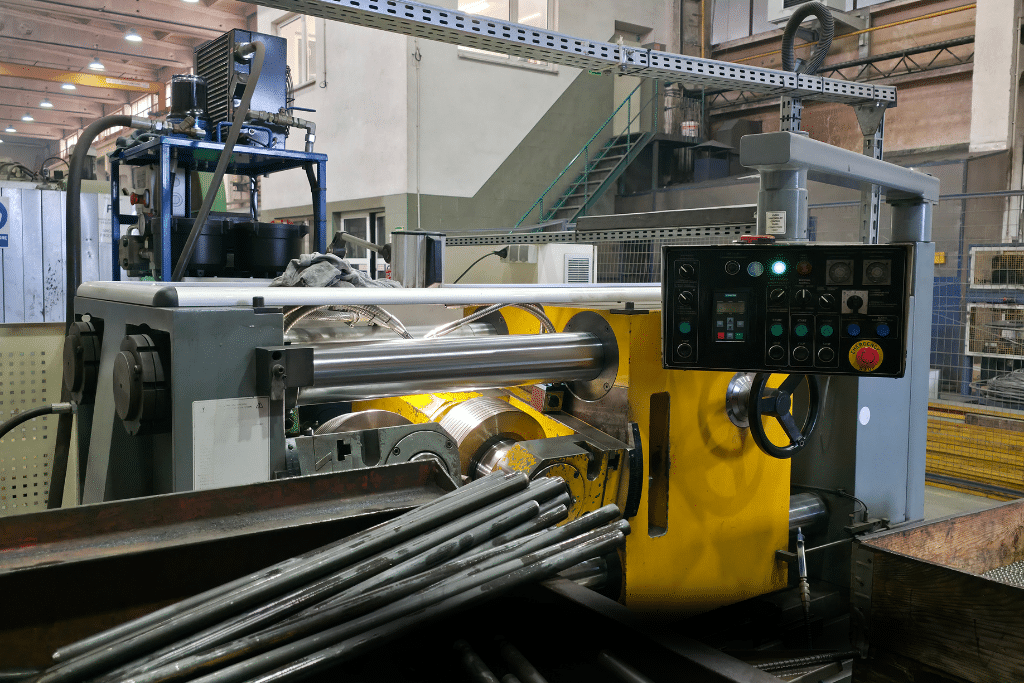

Thread rolling, also known as cold thread rolling, is a method of forming external and internal threads through plastic deformation of the material without cutting. In this process, a steel bar or shaft is pressed between rotating rolling dies that feature a profiled thread shape. The material becomes densified, and the thread is formed by lateral pressure, which eliminates chip formation and minimizes production waste.

This process is particularly effective for structural steel, including high-strength grades used in load-bearing components. Compared to thread milling or turning, thread rolling increases surface hardness.

Operating principles and types of thread rolling

The primary device used is a rolling head with two to three planetary dies that rotate synchronously with the workpiece. In plunge rolling (used for short threads), the bar remains axially stationary while the dies form the thread in a single pass. In the through-feed variant, ideal for long bars (even several meters in length), the material moves axially, enabling continuous production.

Advantages of thread rolling

Thread rolling outperforms cutting in terms of strength—rolled threads have 20–30% higher tensile and fatigue resistance due to the continuous metal fiber structure without microcracks. The thread surface is smooth (Rz < 4 µm), which improves corrosion resistance and reduces friction in bolted connections.

Additional benefits include

Efficiency: Up to 10 times faster than turning, making it ideal for mass production.

Economy: Oszczędność materiału (do 15%) i narzędzi (rolki służą 100 tys. gwintów).

Precyzja: Brak luzów termicznych, tolerancje 6g/6h dla gwintów metrycznych.

Ekologia: Mniej odpadów i energii (o 70% niższe zużycie)

Zastosowania w przemyśle i ofercie Pamexpol

Walcowanie gwintów jest kluczowe w budownictwie stalowym, w energetyce wiatrowej czy mostownictwie zapewnia trwałość w warunkach dynamicznych obciążeń.

Wybierając walcowanie gwintów, inwestujesz w trwałe i ekonomiczne komponenty. W Pamexpol oferujemy kompleksową produkcję z naciskiem na jakość i szybką realizację.

Skontaktuj się z nami po ofertę!